If you already own a mill, even a quite large one, there is still no denying the handiness of the milling attachment for machining the ends of long workpieces, as the z-axis clearance of any lathe is essentially unlimited. Accordingly, it facilitates between-centers, or "line boring" operations.Ģ) It provides for the use of a rear-mounted toolpost.ģ) It enhances the usability of a milling attachment, in that the attachment can be mounted at several locations along the cross slide, in addition to the usual compound rest position.

When completed and installed, the S-4382 slide offers some important advantages over the stock South Bend cross slide:ġ) The t-slotted cross slide, with its substantial horizontal working surface, makes possible certain boring mill-type operations on the lathe. The t-slotted cross slide, in addition to providing the normal functionality of the stock SB cross slide, extends the working surface completely to the rear end of the slide, providing t-slots and additional tapped holes for securing workpieces. I’ve wanted to equip my 9A with one of these since I bought the lathe in ’05, but have only recently got around to it.

I reworked a X2 clone that was doing okay but not great and found out that the ways were crooked like a politician. It was sloppy in front and would bind in the middle and worse towards the end.

I played with such a cross slide in a shop. Plates will be fabricated, then some assembly is in order. Of thread removed from the rear x( 8mm Dia) to mount the Bearing. The X axis lead screw is ready to assemble, the Y axis LS needs to have about 1.125 Then the bearing pocket was bored and two mounting holes were drilled and tapped for the bearing retaining plate. The Base was turned over and the “as cast”surface was milled flat, The Base was positioned in the vise and the Bearing pocket was bored for the 26mm x 8 mm+. 5” CRS Plate.Ģ mounting holes were drilled on the Lead Screw center line on the top & bottom The saddle was removed and replaced with a 6” x 6” x. The dovetails were machined off to accommodate linear Rails on both axes. See: Will build a Benchtop mill including Castings! Comments appreciated. The first Cross Slide I Modified was an “Ultra” Model. However: I will zero my Bridgeport 2J machine, and then check the Table, SaddleĪnd Base castings for the problems you, Hans G and QSPSB described, andĪs noted in an earlier post, the Acme 5/8-10 nuts are BAD and should be replaced! My experience is quite different on the two ENCO, and one Grizzly I purchased. You are the third person on this thread that has remarked about the poor workmanship My thanks to “doorknob” for the wake up call!

If retaining the existing dovetails you may want to machine oiling grooves The X axis nut is cast into the Saddle (item 16) and will have to be machined out and replaced. The Y axis nut (item 3 ) is a press fit into the Base and is easily removed.ģ. The acme nuts (5/8-10) are inferior and should be replaced withĭelrin nuts. Must be turned down to match the bearing (or bushing) you select. The Base (item 1) can be modified to support the rear end of the leadscrew which The Longitudinal Screw Brackets (item 24) and the Transverse Screw Bracket (item 4) This oversight can be corrected by boring bearing pockets in The leadscrews are of excellent quality, but are not riding in bearings.

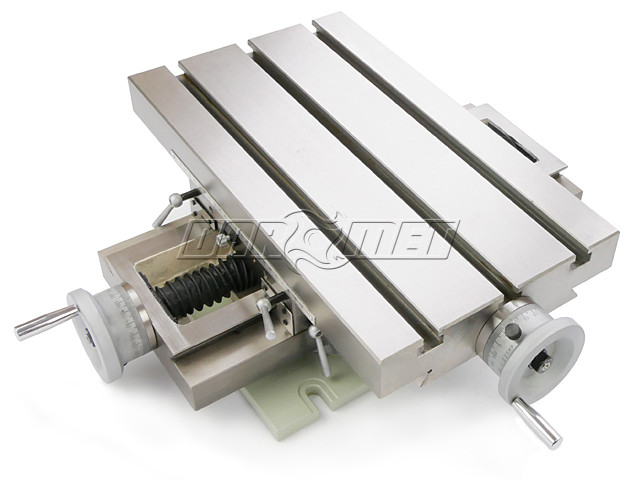

CNC DOVETAIL CROSS SLIDE TABLE MANUAL

Manual operation or a future CNC retrofit!ġ. Making the following modifications will convert your Cross Slide into a valuable asset for The Grizzly & Shars "Taiwanese" Cross Slide is well made but has some serious Would provide a major element in the construction of a sturdy Benchtop Mill. With a Table size of 6” x 18.5” and travels of 12” x 7.5” it This $120.00 Cross Slide has great potential in providing a very fine “low cost” X-Y Table for

0 kommentar(er)

0 kommentar(er)